Pavement Design: More Than Just Asphalt and Concrete

Pavement constructions are big-budget projects and are needed to be durable and perform as per the expected requirements. Therefore, many factors and thoughts go into getting the pavement design right.

Not just knowledge of civil engineering but fair shares of expertise in transportation and geotechnical engineering are required in pavement design to ensure it meets its very objectives.

What are the Objectives of Pavement Design?

A highway pavement structure is made up of superimposed layers of different materials above the natural soil subgrade that primarily ensures

- That the traffic loads from the top layer are distributed properly to the subgrade.

- A good drainage system takes away excess groundwater on the surface to prevent flooding and seepage to the subgrade.

- Safety and accessibility for all users. For district roads, cyclists, pedestrians, and disabled people must be considered.

The other critical aspects of pavement design include preparing the top surface with acceptable riding quality, sufficient skid resistance, advantageous light-reflecting properties, and minimal noise pollution. Sight-distance signage and sufficient road lighting are also important aspects of pavement design.

The ultimate goal is to make sure that the transmitted stresses brought on by the wheel load are sufficiently decreased to avoid exceeding the subgrade’s bearing capability.

What are the Two Principal Types of Pavements?

There are two main types of road surfaces and pavement construction methods:

- Flexible pavement – typically consists of multiple layers, with the top layer made of asphalt

- Rigid pavement – made of one layer of cement concrete

Although there can be many types of roads, especially in rural areas, asphalt and concrete pavement are the two main types of pavement found overwhelmingly across the world.

Flexible Pavement Design

Flexible pavement got its name because the entire pavement structure flexes or deflects, under wheel loads. A flexible pavement construction is often made up of multiple layers of materials. Starting from the top, each layer passes loads to the layer right below. The load received by a layer is distributed and further passed on to the next layer below.

As a result, the stresses get lowered, which are highest at the top layer and lowest when reaching the subgrade. To make the most of this mechanism, layers are typically stacked in descending order of load-bearing capacity, with the highest load-bearing capacity material (and the most expensive) at the top and the lowest load-bearing capacity material (and least expensive) at the bottom.

Flexible Pavement Structure

Flexible road construction is usually done with a few layers of granular material spread and compacted over the subgrade. Naturally obtained materials are frequently used, although manufactured aggregates provide better performance.

The layers are wetted to facilitate compaction, causing the particles to interlock and densify. When numerous layers are employed, the lowest layer has a coarser grade.

Different Layers of Flexible Pavement

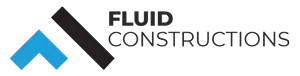

Typically, a traditional flexible pavement contains layers such as seal coat, surface course, tack coat, binder course, prime coat, base course, sub-base course, compacted sub-grade, and natural sub-grade.

Flexible pavement construction technique

Flexible pavements are constructed using one of the following techniques:

- Conventional layered flexible pavement

- Full-depth asphalt pavement.

- Contained rock asphalt mat (CRAM),

In conventional flexible pavement systems, high-quality, costly materials are used in the top layer, where stresses are greatest, and the lower layers are composed of lower-quality, less expensive materials.

The construction of full-depth asphalt pavements involves the direct application of bituminous layers onto the subgrade soil. When there is a lot of traffic and local resources are unavailable, this is more appropriate.

To create contained rock asphalt mats, dense/open-graded aggregate layers are sandwiched between two asphalt layers. By applying modified dense-graded asphalt concrete above the subgrade, you may shield it from surface water and considerably reduce the vertical compressive pressure on the soil subgrade.

Rigid pavement design

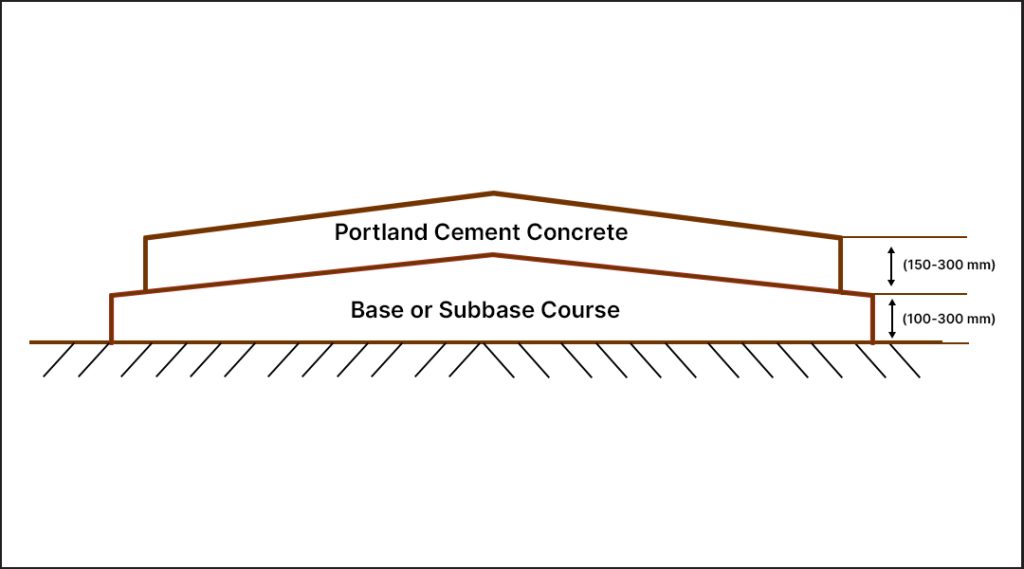

Cement concrete is the material used in rigid pavement. Unlike flexible pavements, rigid pavements are rigid, meaning they do not flex significantly under traffic loads. So, in the case of rigid or concrete pavement design, the high modulus of elasticity and rigidity of the concrete slab account for the majority of its load-carrying capability.

The picture below depicts a typical cross-section of the stiff pavement. Rigid pavements are laid either directly on the prepared subgrade or on a single layer of stabilised or granular material, in contrast with the multiple layers used in flexible pavement.

The slab action is how the rigid pavements distribute the loads. The concrete slabs of the pavement behave like elastic plates suspended in a viscous fluid.

Rigid pavements are constructed from Portland cement concrete and should be analysed by plate theory, assuming an elastic plate rests on a viscous foundation.

Types of Rigid Pavements

Rigid pavements can be classified into four types:

- Jointed plain concrete pavement (JPCP),

- Jointed reinforced concrete pavement (JRCP),

- Continuous reinforced concrete pavement (CRCP), and

- Pre-stressed concrete pavement (PCP).

Rigid pavement failure criteria

For rigid pavement design, fatigue cracking has historically been regarded as the primary or the only criterion. The stress ratio between the flexural tensile stress and the concrete modulus of rupture determines the maximum number of load repetitions, which is the main cause of fatigue cracking.

Of late, pumping is being recognised as a significant cause of failure in the rigid pavement. Pumping is the process of forcing soil slurry through the joints of cement concrete slabs and the cracks on the slabs that might be produced due to the down and up movements of the slabs under heavy loads of wheels. The other causes of distress in rigid pavements are spalling, faulting, and degradation of slabs.

How do geotechnical and environmental factors affect road pavement design?

Geotechnical engineering is an important aspect of road and highway design. Geotechnical engineers assess the project site’s soil and rock conditions to determine the foundation design and roadway stability. When planning the roadway’s foundation, they take into account aspects including soil type, groundwater level, and slope stability.

The impact on the environment is taken into consideration when designing roads and highways. When planning a route, the design team has to take into account things like wildlife habitats, cultural resources, and the quality of the air and water. They also need to consider the pavement’s long-term sustainability, which includes cutting carbon emissions and using recycled materials.